LION™ 350 60:1 Pump

Designed for 35 lb, 120, and 400 lb. containers. Ideal for the users that need reliable grease delivery and medium length systems that have multiple dispense points. This Lion grease pump delivers up to 4.4 lb (2 kg) per minute.

Fluids Handled

Part No.:

1450-012 - Lion™ 60:1 Grease 120 lbs

1450-011 - Lion™ 60:1 Grease 400 lbs

Markets Served:

Warning! Do not use any Lion™ series products with flammable fluids.

Verify fluid compatibility with MSDS sheets.

Contact Balcrank for pumping grease higher than NLGI-2 and specific system design performance technical data.

LION™ 350 60:1 Inductor

Lion™ 350 60:1 grease pump is used with 120 and 400 lb drums. The air operated pump hoist lifts and lowers the pump, making drum changes easier, faster and safer. The pump’s lower end is rigidly fixed to a follower plate with a single rubber lip. The weight of the pump, pump bracket and follower plate plus atmospheric pressure push the assembly against the grease eliminating channeling and air pockets, keeping grease free from contaminants, minimizing waste, and aiding pump priming.

Fluids Handled

Part No.:

Includes:

1450-012 Lion 60:1 Grease 120 lbs pump

4450-003 Inductor, Gravity, Pump Lift & Follower Plate

1451-008 - Lion™ 60:1 Grease 400 lbs Package, Lion™ 350, 60:1 Inductor

Includes:

1450-011 Lion 60:1 Grease 400 lbs pump

4450-003 Inductor, Gravity, Pump Lift & Follower Plate

4450-006 - Hoist w/ Inductor plate 120 lb (no pump)

4450-006 - Hoist w/ Inductor plate 400 lb (no pump)

4450-005 - Base plate for pump hoist & inductor

Markets Served:

Verify fluid compatibility with MSDS sheets.

Contact Balcrank for pumping grease higher than NLGI-2 and specific system design performance technical data.

LION™ 450 25:1 Pump

This medium pressure double ball pump can be used for both grease and oil in high volume medium pressure bulk transfer applications. The construction of the pump allows for dual use for grease systems that don’t require high pressure or a high volume medium pressure oil system.

Fluids Handled

Part No.:

Markets Served:

1) Maximum air consumption with 5 bar air inlet pressure and 80 cpm.

(2) Maximum noise level measured at 1 m from the pump, 7 bar air pressure and free delivery.

Warning! Do not use any Lion™ 450/600 series products with flammable fluids.

Verify fluid compatibility with MSDS sheets.

Contact Balcrank for pumping grease higher than NLGI-2 and specific system design performance technical data.

LION™ 450 40:1 Pump

Designed for medium volume applications that require higher flow and pressure delivery. This pump can be used with a follower plate system, combined with a gravity inductor system, or a double post RAM for simultaneous dispense, and higher flow applications.

Fluids Handled

Part No.:

1450-002 - Lion™ 450 40:1 grease 400 lb drum pump

1450-004 - Lion™ 450 40:1 grease bulk tote pump

Markets Served:

(1) Air consumption at 5 bar air pressure, NLGI-0 grease at 20º C and 80 cpm.

(2) Noise level measured at 1 m from the pump, 7 bar air pressure and free delivery.

Warning! Do not use any Lion™ 450/600 series products with flammable fluids.

Verify fluid compatibility with MSDS sheets.

Contact Balcrank for pumping grease higher than NLGI-2 and specific system design performance technical data.

LION™ 450 70:1 Pump

Designed for very cold environments and/or applications where only medium pressure air is available to power the pump which could limit the performance and application of greasing. This pump can be used with a follower plate system, combined with a gravity inductor system, or a double post RAM for simultaneous dispense or higher flow applications.

Fluids Handled

Part No.:

1450-005 - Lion™ 450 70:1 grease 400 lb drum pump

1450-007 - Lion™ 450 70:1 grease bulk tote pump

Markets Served:

(1) Air consumption at 5 bar air pressure, NLGI-0 grease at 20º C and 80 cpm.

(2) Noise level measured at 1 m from the pump, 7 bar air pressure and free delivery.

(3) Pump air limited to 100 psi (7 bar) due to connecting hose pressure limits.

Warning! Do not use any Lion™ 450/600 series products with flammable fluids.

Verify fluid compatibility with MSDS sheets.

Contact Balcrank for pumping grease higher than NLGI-2 and specific system design performance technical data.

LION™ 600 12:1 Pump

Medium pressure grease pump for very high volume applications. Bulk transfer of grease from large containers to drums or pails, lube trucks or other transfer applications at high delivery rates. Pump comes with a 3” camlock for easy installation into grease totes.

Fluids Handled

Part No.:

Markets Served:

(1) Air consumption at 5 bar air pressure, NLGI-0 grease at 20º C and 80 cpm.

(2) Noise level measured at 1 m from the pump, 7 bar air pressure and free delivery.

Warning! Do not use any Lion™ 450/600 series products with flammable fluids.

Verify fluid compatibility with MSDS sheets.

Contact Balcrank for pumping grease higher than NLGI-2 and specific system design performance technical data.

LION™ 600 80:1 Pump

Designed for very cold environments and/or applications where only medium pressure air is available to power the pump which could limit the performance and application of greasing. This pump can be used with a follower plate system, combined with a gravity inductor system, or a double post RAM for simultaneous dispense, or higher flow applications. Similar to the Lion™ 450 70:1 pump but operates at lower cycle rates for severe environments.

Fluids Handled

Part No.:

1450-008 - Lion™ 600 80:1 grease 400 lb drum pump

Markets Served:

(1) Air consumption at 5 bar air pressure, NLGI-0 grease at 20º C and 80 cpm.

(2) Noise level measured at 1 m from the pump, 7 bar air pressure and free delivery

(3) Pump air limited to 100 psi (7 bar) due to connecting hose pressure limits.

Warning! Do not use any Lion™ 450/600 series products with flammable fluids.

Verify fluid compatibility with MSDS sheets.

Contact Balcrank for pumping grease higher than NLGI-2 and specific system design performance technical data.

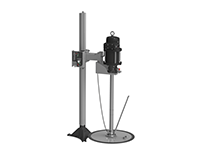

LION™ Inductor

Lion™ 450 and Lion™ 600 grease pumps are used with 400 lb drums in applications where higher volumes of grease are required. The air operated pump hoist lifts and lowers the pump, making drum changes easier, faster and safer. The pump’s lower end is rigidly fixed to a follower plate with a single rubber lip. The weight of the pump, pump bracket and follower plate plus atmospheric pressure push the assembly against the grease eliminating channeling and air pockets, keeping grease free from contaminants, minimizing waste and aiding pump priming.

Fluids Handled

Part No.:

Includes:

1450-002 Lion™ 450, 40:1 pump

4450-003 Inductor, Gravity, Pump

Lift & follower plate

1451-005 - Package, Lion™ 450, 70:1 Inductor

Includes:

1450-002 Lion™ 450, 40:1 pump

4450-003 Inductor, Gravity, Pump

Lift & follower plate

1451-006 - Package, Lion™ 600, 80:1 Inductor

Includes:

1450-008 Lion™ 600, 80:1 pump

4450-003 Inductor, Gravity, Pump

Lift & follower plate

4450-005 - Base plate for pump hoist & inductor

4450-003 - Inductor, Gravity, Pump Lift & follower plate

833650 - Fixed inductor plate for Lion™ 450 & 600 (kit only)

Markets Served:

Warning! Do not use any Lion™ 450/600 series products with flammable fluids.

Verify fluid compatibility with MSDS sheets.

Contact Balcrank for pumping grease higher than NLGI-2 and specific system design performance technical data.

LION™ Inductor, Double Post RAM

Lion™ 450 and Lion™ 600 grease pumps are used with 400 lb. drums in applications where high volumes of grease are required, environmental temperatures are low or higher viscosity greases are used. The air operated double post RAM inductor features controlled RAM pressure to assist in pump priming. When the double lip inductor plate is rigidly attached to the lower end of the pump tube, the weight of the pump and lift pneumatic pressure of the RAM plus atmospheric pressure on the material forces and improves pump priming. The inductor plate also serves as protection against contaminants and eliminates material waste. For use with 400 lb. (185 kg) drums.

Unit also includes guide rods, drum retaining mechanism and a control box with the following features:

• On-off control of the pump

• Up-down control of the RAM (drum exchange)

• Two independent air pressure regulators, one for the pump and for the power RAM cylinders

• Pump independent air pressure gauge

• Empty drum shut-off safety feature

• Automatic vacuum release

* When using this RAM with the 12:1, contact Balcrank customer service for additional needed components

Fluids Handled

Part No.:

Includes:

1450-003 Lion™ 450, 40:1 pump

4450-004 Double Post Inductor

833650 Kit, Collar/Follower-Plate

1451-002 - Package, Lion™ 450, 70:1 pump. Double Post Inductor.

Includes:

1450-006 Lion™ 450, 70:1 pump

4450-004 Double Post Inductor

833650 Kit, Collar/Follower-Plate

1451-003 - Package, Lion™ 600, 80:1 pump. Double Post Inductor.

Includes:

1450-009 Lion™ 600, 80:1 pump

4450-004 Double Post Inductor

833650 Kit, Collar/Follower-Plate

1451-007* - Package, Lion™ 600, 12:1 pump. Double Post Inductor.

Includes:

1450-010 Lion™ 600, 12:1 pump

4450-004 Double Post Inductor

includes 3” Cam-lock for mounting

pump to inductor plate

4450-004 - Inductor, double post air operated